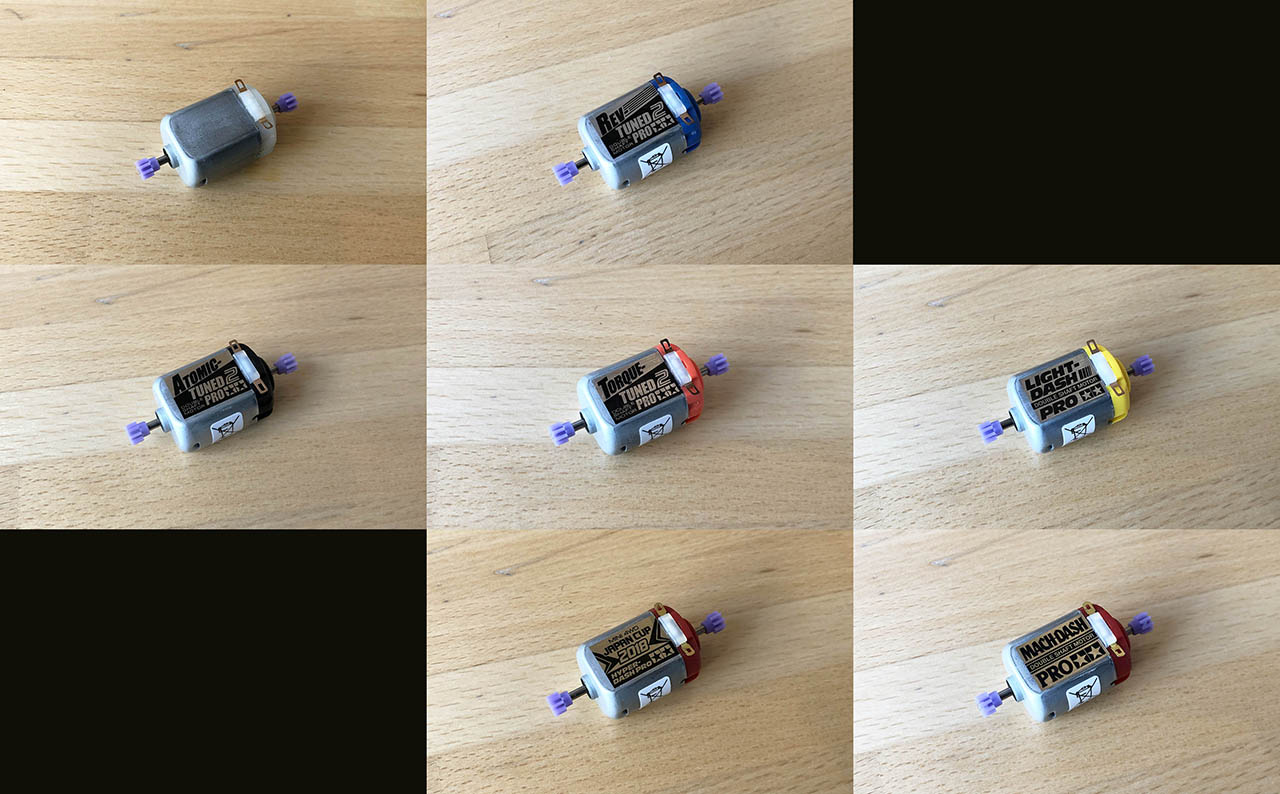

You can make your very own Ultra-Dash PRO with the same enameled insulated copper wire in an Ultra-Dash motor on a Hyper-Dash PRO motor core.

Ultra-Dash

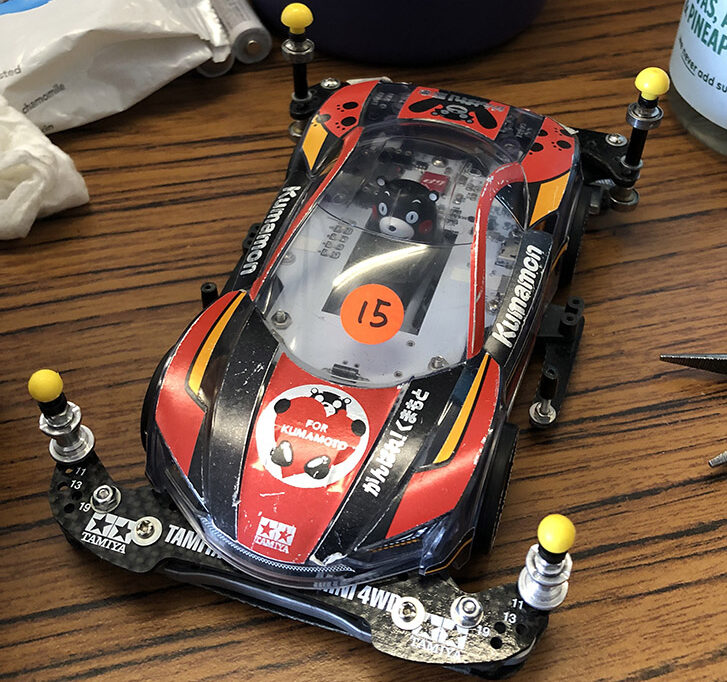

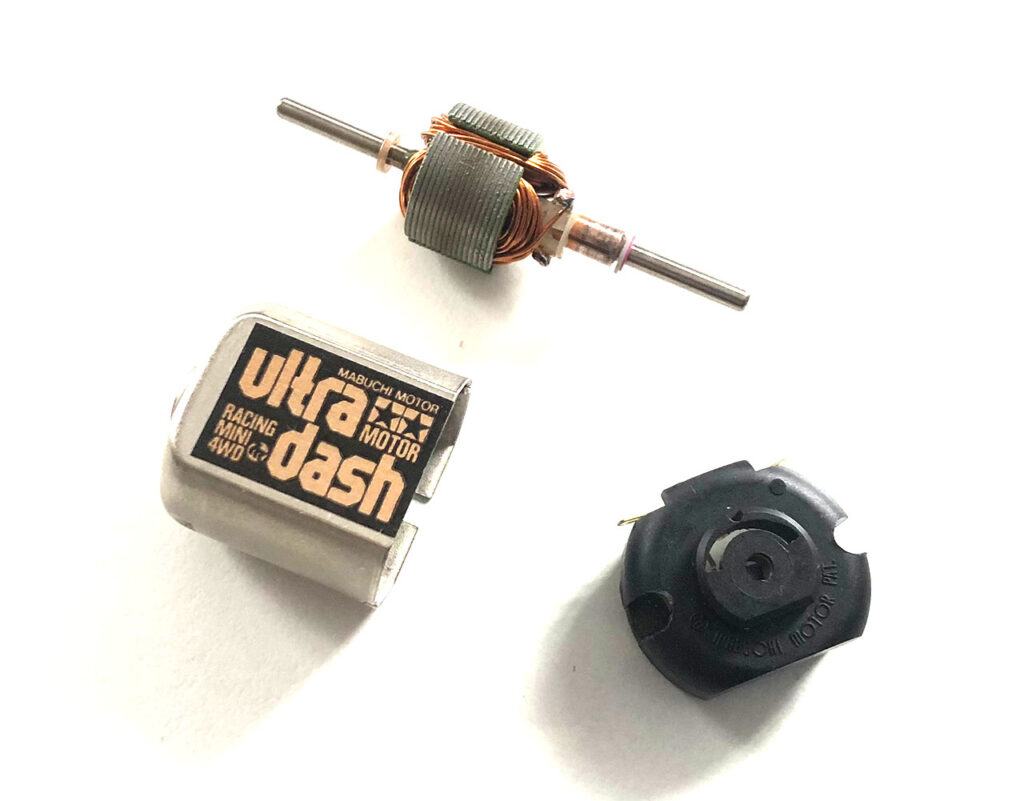

Let’s examine the Tamiya Mini 4WD Ultra-Dash Motor motor core, to do that we had to dismantle the motor, open the motor case clips, carefully pull out the black motor bell end with the motor core and then pull the motor core out without breaking the motor brushes as we will need to reuse them.

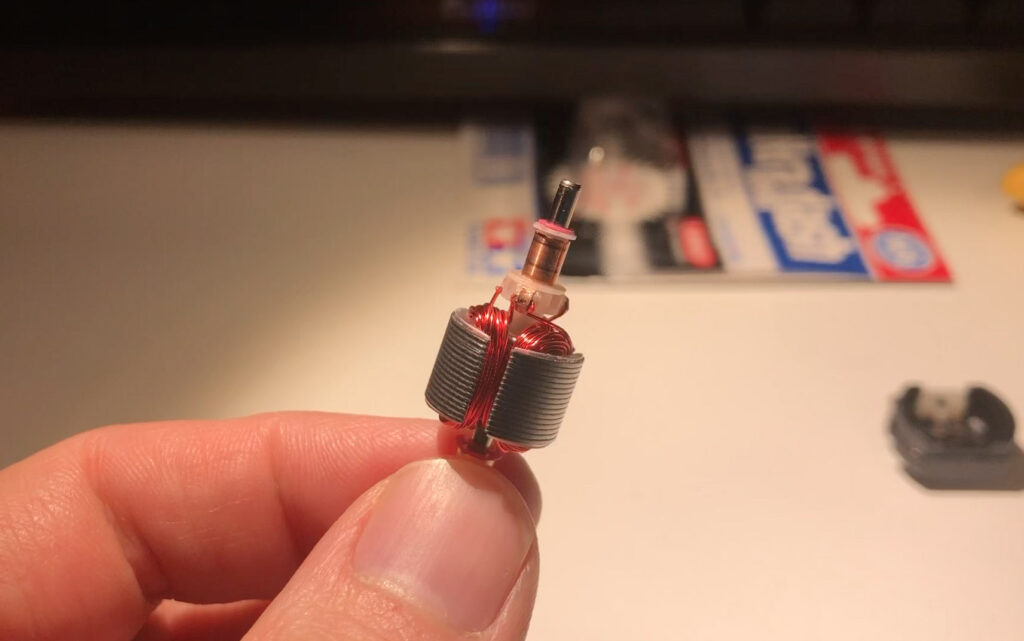

Here is a picture of an Ultra-Dash motor core (see picture below). The Ultra-Dash uses 0.37mm enameled insulated copper wire. The wire coating colour is red. Each section has 25 turns and it is wound in an anti-clockwise direction.

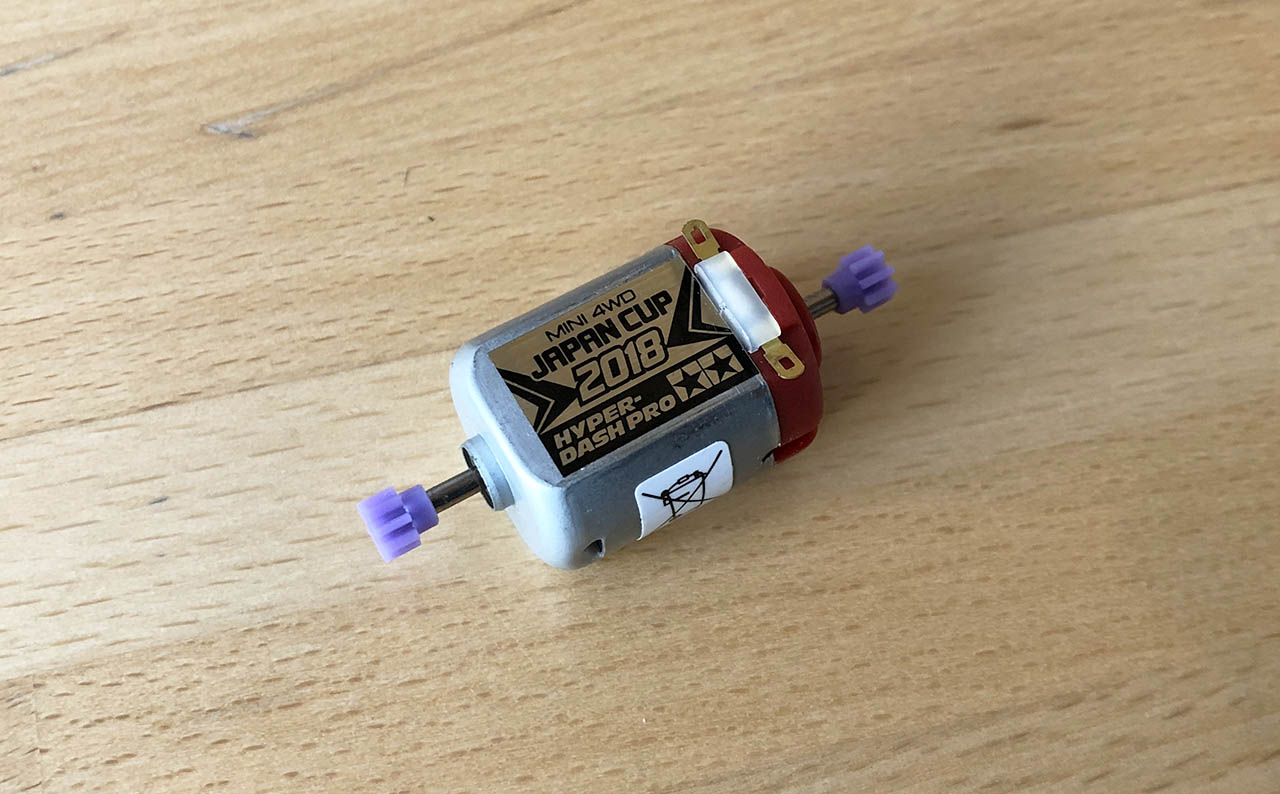

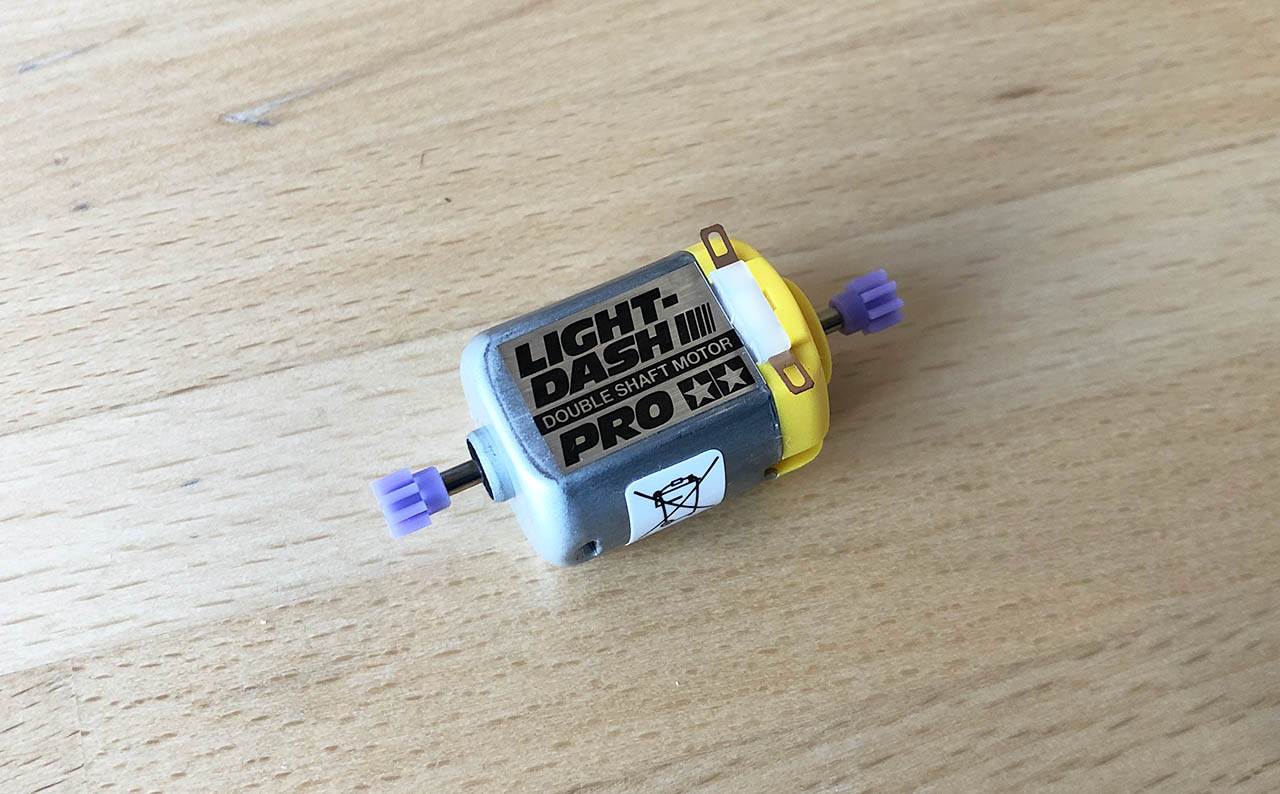

Hyper-Dash PRO

Let’s do the same to a Hyper-Dash PRO motor.

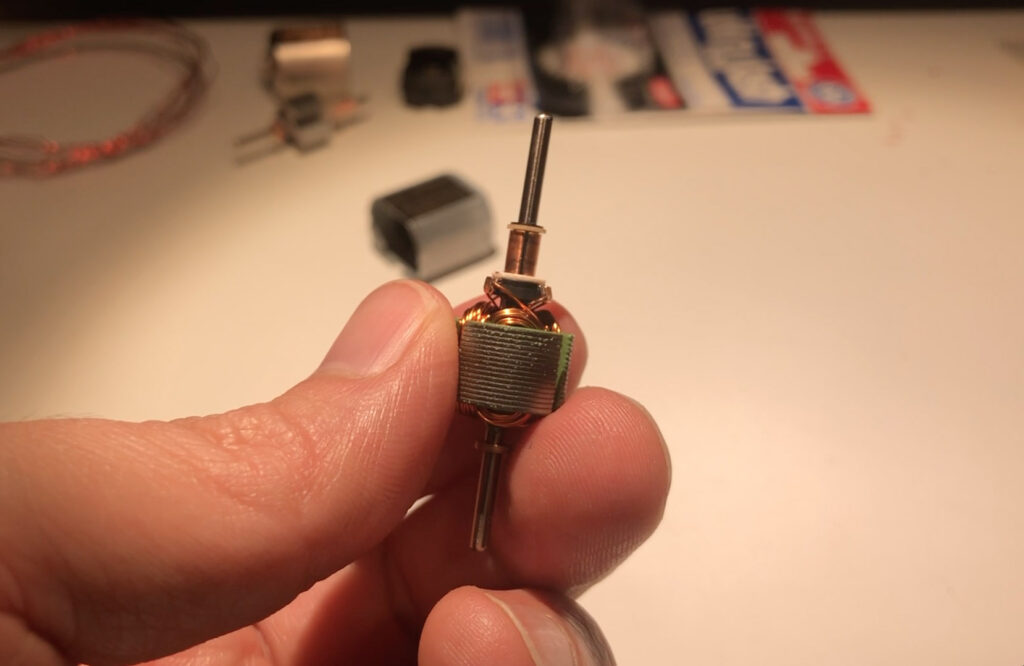

Here is a picture of a Tamiya Mini 4WD Hyper-Dash PRO motor core (see picture below). The Hyper-Dash uses 0.3mm enameled insulated copper wire. The wire coating colour is golden copper. Each section has 34 turns and it is also wound in an anti-clockwise direction.

Making your own

You can make your very own Ultra-Dash PRO with the same 25 turns 0.37mm wire in an Ultra-Dash on a Hyper-Dash motor core.

You will need

- a brand new Ultra-Dash motor

- a Hyper-Dash Pro motor (new or old doesn’t matter as long as the motor core is still good)

- some good quality 0.37mm enameled insulated copper wire (in any colour you like). 5 metres or more.

- a wire clipper

- a good soldering iron with solder

Prepare

Carefully dismantle the two motors. Open the motor case clips, carefully pull out the motor bell end with the motor core and then pull the motor core out without breaking the motor brushes as we will need to reuse them.

With the help of a wire clipper, take the enameled insulated copper wire out of the Hyper-Dash PRO motor core. Observe how the wire is wound around each section. Clear the wire around the hooks.

It is optional, but if you would like to use the Ultra-dash commutator instead of the Hyper-dash one, you will need to take the copper wire out of the Ultra-dash motor core, extract the commutator and replace the ones on the Hyper-dash core. We decided to do this to get the best matching motor brush and commutator.

Make the core

Holding the prepared Hyper-Dash motor core, wind the 0.37mm enameled insulated copper wire into a coil neatly and tight in an anti-clockwire direction. After 25 round, loop the wire over the hook, sand/scrap off the enamel coating off the bit of the wire that touches the hook and continue to the next section. And repeat. Once you have completed all three sections. Use the soldering iron to solder the wire to the hooks.

Put together

Put the new motor core into the black motor bell end with extra care on the motor brushes, make sure they sit neatly on the commutator. Then put the set into the motor casing. Bend the clips down to secure the parts.

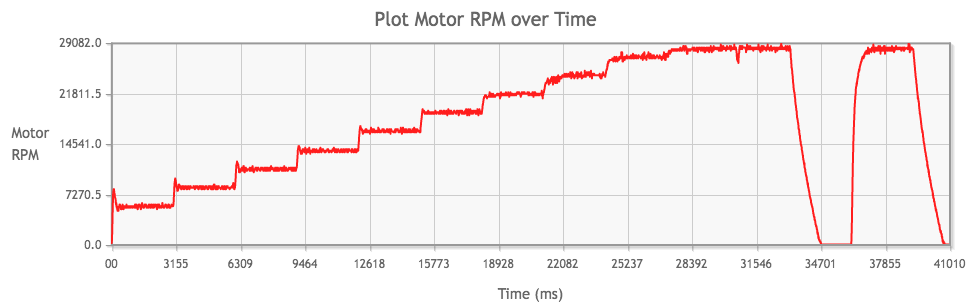

Testing

We tested our homemade Ultra-Dash PRO motor, driving all 4 wheels and not under load. Our motor managed to get a top speed of 29,082rpm (see chart below). Tamiya 15307 Mini 4Wd Ultra-Dash Motor spec is 24,000 – 27,500rpm. So it seems like our homemade Ultra-Dash PRO performs okay. We look forward to testing the motor on the track and see how it compares with Hyper-Dash PRO and Mach-Dash PRO.

Have you made one yourself? How fast does it go?

![7 different Tamiya Mini 4WD low profile small diameter tyres [Item no: 95208, 95205,95152, 95281, 95304]](https://mini4science.com/wp-content/uploads/2024/09/IMG_0538_mod2-150x150.jpg)

![8 different Tamiya Mini 4WD metal rollers [Item no: 95612, 15522, 95643, 95497, 15426, 95160, 15345, 15475]](https://mini4science.com/wp-content/uploads/2024/07/IMG_0296-150x150.jpg)

![7 different Tamiya Mini 4WD low profile small diameter tyres [Item no: 95208, 95205,95152, 95281, 95304]](https://mini4science.com/wp-content/uploads/2024/09/IMG_0538_mod2.jpg)

![8 different Tamiya Mini 4WD metal rollers [Item no: 95612, 15522, 95643, 95497, 15426, 95160, 15345, 15475]](https://mini4science.com/wp-content/uploads/2024/07/IMG_0296-scaled.jpg)